OUR SERVICES

Design and Engineering Services

Skilled in Civil, Structure, and Piping Engineering & Design, our team of affiliated engineering companies provides a comprehensive review of all drawings & plans, ensuring a high level of expertise on every project.

Fabrication, Assembly and Blast & Coatings

Our extensive fabrication shop capabilities, combined with a sizeable blast & coatings operation give ISTI the unique ability to handle numerous large-scale projects simultaneously.

Field Construction and Site Support

Our field experts specialize in every discipline of the fabrication and installation process, ensuring precision construction on the tightest of time frames, without compromising quality.

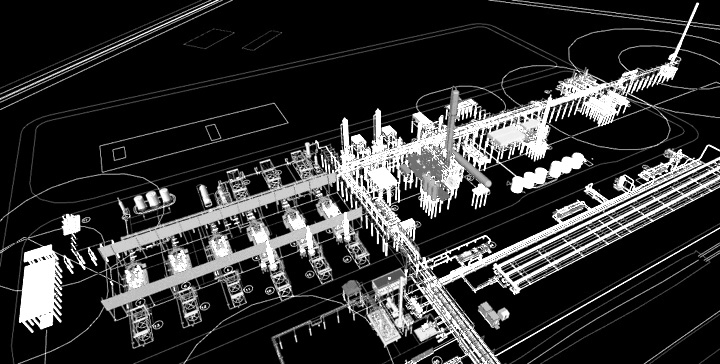

Turnkey Solutions

ISTI’s turn-key approach begins with comprehensive plant design and engineering services using our affiliated engineering companies. We have a proven track record of completing large jobs to the complete satisfaction of our customers.

Our team is skilled in civil, structure, and piping engineering and design, and provides comprehensive reviews of all drawings and plans, ensuring a high level of professional expertise on every project.

Whether your project calls for equipment modification, small single skid units, or pre-fabrication pipe and structural steel for an entire plant, ISTI’s engineering & design team can help develop an optimal solution that will get you there with speed, quality, safety, and reduced cost. Regardless of project scope or size, ISTI can help manage your project from start to finish, and do so on time and on budget.

Precision Craftsmanship

Our family of craftsmen are the key to our success and experts at what they do. Their exceptional work is driven by integrity, and a strong desire to deliver the highest quality projects possible. They share the ISTI commitment to exceeding expectation and participate in ongoing training that keeps them on the leading edge of current industry technologies. It is that exceptional workforce, combined with our extensive pipe and steel fabrication shop capabilities, and sizable blast & coatings operation, that gives ISTI the unique ability to handle numerous large-scale projects simultaneously.

Whether your project calls for small single skid units, pre-fabrication pipe and structural steel for an entire plant, or an 80 module Sulfur Recovery Unit processing 500,000 tons annually, ISTI’s comprehensive facilities & ample workforce, experienced in all areas of field construction including: Civil, Structural, Piping, Fabrication, Prep & Painting, Insulation, Heavy Rigging, Instrumentation & Electrical, will ensure our company motto is achieved “Your Job. Done Right.”

Paint Process

Our 44,000 square foot interior blasting and painting facilities provide an immaculate environment for more than 100 paint and finishing professionals.

We offer a wide range of finish options, from epoxy and urethane to specialized tank coatings. Paint and finishes are thoroughly retouched after assembly, both inside the plant prior to delivery as well as at the project’s final site in the field.

Reduce Costs & Speed Production

Our strategy includes the construction of skid based modules in our expansive shops in Tulsa, Oklahoma. After fabrication, assembly and coating, we trial fit and test in our yard, prior to shipment. This allows ISTI to deliver your product to the field knowing that we are ready for assembly. This process reduces your cost and speeds your job to final commissioning.

We strive to give our clients the peace of mind of knowing they can depend on us for expert solutions, first-rate service, and exceptional products delivered on time and exactly to their specifications.

We are perfectionists at ISTI

ISTI Plant Services is lead by an expert team of managers, supervisors, and foremen with more than 150 years combined plant construction experience. Our field experts specialize in every discipline of the fabrication and installation process, ensuring precision construction on the tightest of time frames, without compromising quality or safety. They are able to take on complex work and bring it to a conclusion with confidence.

The cornerstone of our business is the safe and successful completion of field construction jobs, and we recognize how critical our clients’ field support needs can be. To ensure those needs are met, we are available 24/7/365 to respond quickly to any emergencies or concerns.

Once construction of a plant is complete on our clients’ site, our professionals retouch the finish to its pristine pre-shipped condition. We won’t leave the site until we know our clients are 100% satisfied.

Transportation & Tulsa Port of Catoosa

The 2500 acre Port of Catoosa is Tulsa’s “unsung” shipping hero, delivering a unique capability to Tulsa businesses as one of the largest inland ports in the United States.Located at the head of navigation for the McClellan-Kerr Arkansas River Navigation System, the Port of Catoosa offers year-round barge, rail and truck transportation services, and can handle and trans-load more than five million tons of cargo per year.

The McClellan-Kerr Arkansas River Navigation System is a 440-mile waterway linking Oklahoma and the surrounding states to ports on the nation’s inland water transport system. The Port of Catoosa is located at the head of the navigation for the system where the waterway travels to the Mississippi River at Montgomery Point. The 18 locks and dams on the McClellan-Kerr create a “staircase” where, in an average year, 13 million tons of cargo is transported.

In addition to navigable waters, the Port of Catoosa is served by three Class I rail carriers – the BN-SF, the Union Pacific and the Kansas City Southern (via a short line switch on the South Kansas and Oklahoma Railroad). It is a scheduled service point for all three carriers, with rail transit times for most bulk cargo roughly equal to barge within 750 miles and days shorter beyond 1000 miles.

The Port is also served by most nationwide contract trucking carriers averaging over 900 trucks per day. Located in the geographic center of the US, truck traffic can reach either coast in just two days. From the Port of Catoosa, ISTI is able to ship to the Port of Houston via truck in one day and to the Port of New Orleans in 11 to 13 days via barge. The availability of shipping options from the Port of Catoosa is an integral part of the ISTI success story.

Turnkey Shipping & Logistics

To ensure efficient delivery of clients’ equipment to their project sites, ISTI employs a synergistic approach that involves utilizing only quality transportation vendors with a successful work history of delivering heavy industrial types of projects to their destinations.